What are the fuels for steam generators?

The steam generator is a kind of steam boiler, but its water capacity and rated working pressure are smaller, so it is more convenient to install and use, and it is mostly used for production and processing by small business users.

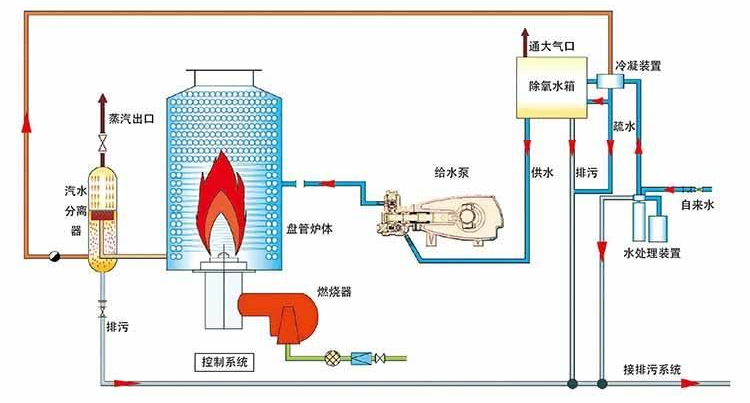

Steam generators are also called steam engines and evaporators. It is the working process of burning other fuels to produce heat energy, transferring heat energy to the water in the boiler body, raising the temperature of the water, and finally converting it into steam.

Steam generators can be subdivided according to different categories, such as horizontal steam generators and vertical steam generators according to product size; According to the type of fuel, it can be divided into electric steam generator, fuel oil steam generator, gas steam generator, biomass steam generator, etc. Different fuels make the operating cost of steam generators different.

The fuel used by the fuel-fired gas steam generator is natural gas, liquefied petroleum gas, biogas, coal gas and diesel oil, etc. It is currently the most widely used evaporator, and its operating cost is one-half of that of an electric steam boiler. It is clean and environmentally friendly. Features, the thermal efficiency is above 93%.

The fuel used by the biomass steam generator is biomass particles, and the biomass particles are processed from crops such as straw and peanut shells. The cost is relatively low, which reduces the operating cost of the steam generator, and its operating cost It is one quarter of the electric steam generator and one half of the fuel gas steam generator.However, the emissions from biomass steam generators are relatively polluting to the air. Due to environmental protection policies in some areas, biomass steam generators are gradually being eliminated.