What is concrete steam curing? Why Steam Curing of Concrete?

Concrete is the cornerstone of construction. The quality of concrete determines whether the finished building is stable. There are many factors that affect the quality of concrete, among which temperature and humidity are the biggest problems.

In order to speed up the growth of concrete strength, steam curing can be used. Steam is used to heat the concrete so that the concrete hardens rapidly under conditions of higher temperature (70~90℃) and higher humidity (about 90% or more). However, natural maintenance is still suitable in areas with brighter and warmer climates. This can save fuel and corresponding investment in a set of equipment and reduce costs.

Concrete maintenance in the cold season.

The best temperature for concrete molding is 10℃-20℃. If the newly poured concrete is in an environment below 5℃, the concrete will be frozen. The freezing will stop its hydration and the concrete surface will become crispy. Loss of strength, severe cracks may occur, and the degree of deterioration will not be restored if the temperature rises.

Protection in hot and dry environments

Moisture is very easy to volatilize under dry and high-temperature conditions. If concrete loses too much water, the strength of the concrete on its surface is easily reduced. At this time, dry shrinkage cracks are prone to occur, which are mainly plastic cracks caused by premature setting of concrete. Especially during concrete construction in the summer, if the maintenance methods are not properly implemented, phenomena such as premature setting, plastic cracks, reduction in concrete strength and durability will occur frequently, which not only affects the construction progress, but also the important thing is to form the structure in this way. The overall quality of the object cannot be guaranteed.

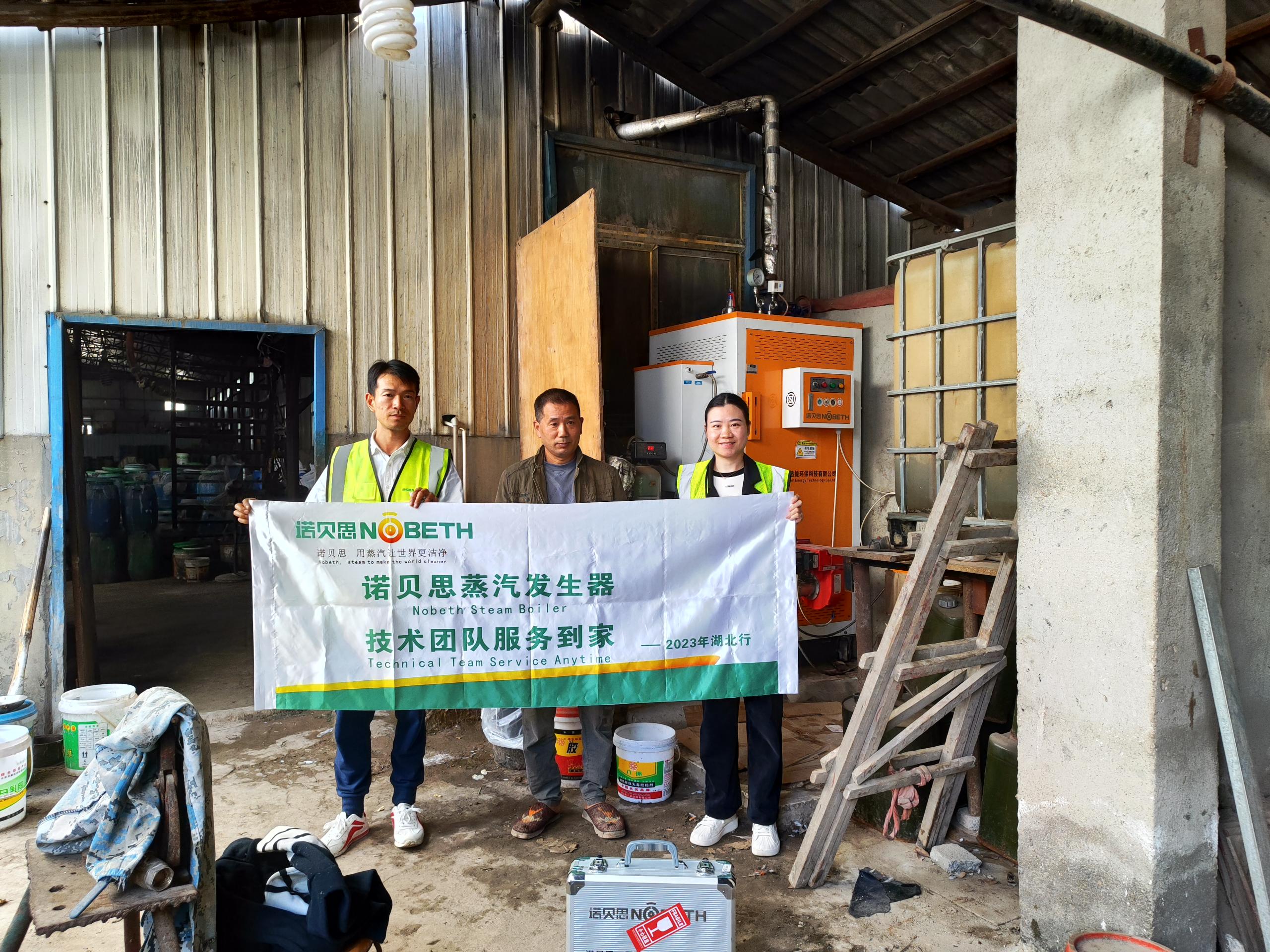

The high-temperature steam generated by Nobeth steam generator creates an environment with suitable temperature and humidity, causing the concrete to solidify and harden, gradually reaching the strength required by the design. The Nobeth steam generator can generate high-temperature steam in a short time to perform steam curing of prefabricated components. The method is also very simple. You only need to cover the concrete with canvas and introduce the high-temperature steam generated by the Nobis steam generator.