Q:Why does a steam generator need a water softener?

Since the water in the steam generator is highly alkaline and high-hardness wastewater, if it is not treated for a long time and its hardness continues to increase, it will cause scale to form on the surface of the metal material or form corrosion, thus affecting the normal operation of the equipment components. Because hard water contains a large amount of impurities such as calcium, magnesium ions and chloride ions (higher calcium and magnesium ions content)). When these impurities are continuously deposited in the boiler, they will produce scale or form corrosion on the inner wall of the boiler. Using soft water for water softening treatment can effectively remove chemicals such as calcium and magnesium in hard water that are corrosive to metal materials. It can also reduce the risk of scale formation and corrosion caused by chloride ions in the water.

1. The softening device converts hard water with high hardness into soft water, which improves the safe operation coefficient of the boiler and system.

Through soft water treatment, the risk of boiler scaling is reduced and the life of the boiler is extended. 2. The softened water system has no corrosive effect on metal surfaces and will not have any impact on equipment and systems. 3. It can improve the cleanliness of water supply and the stability of water quality. 4. Soft water can recover heat energy, reduce heat energy loss and save electricity. 5. No pollution to the environment and sustainable development.

2. Improve thermal energy utilization, reduce electricity consumption, and save electricity bills.

If soft water is used as the heat exchange medium, the heat transfer efficiency can be improved under the same steam pressure. Therefore, by softening the water quality to a certain standard, the operating costs of the steam boiler will be reduced. In addition, when using electric heating boilers or gas-fired boilers, heating is generally performed without an external power supply (that is, water is used as the heating medium), and softened water can reduce the load of the steam boiler to less than 80% of the rated load;

3. The service life of the boiler is extended and maintenance costs are reduced.

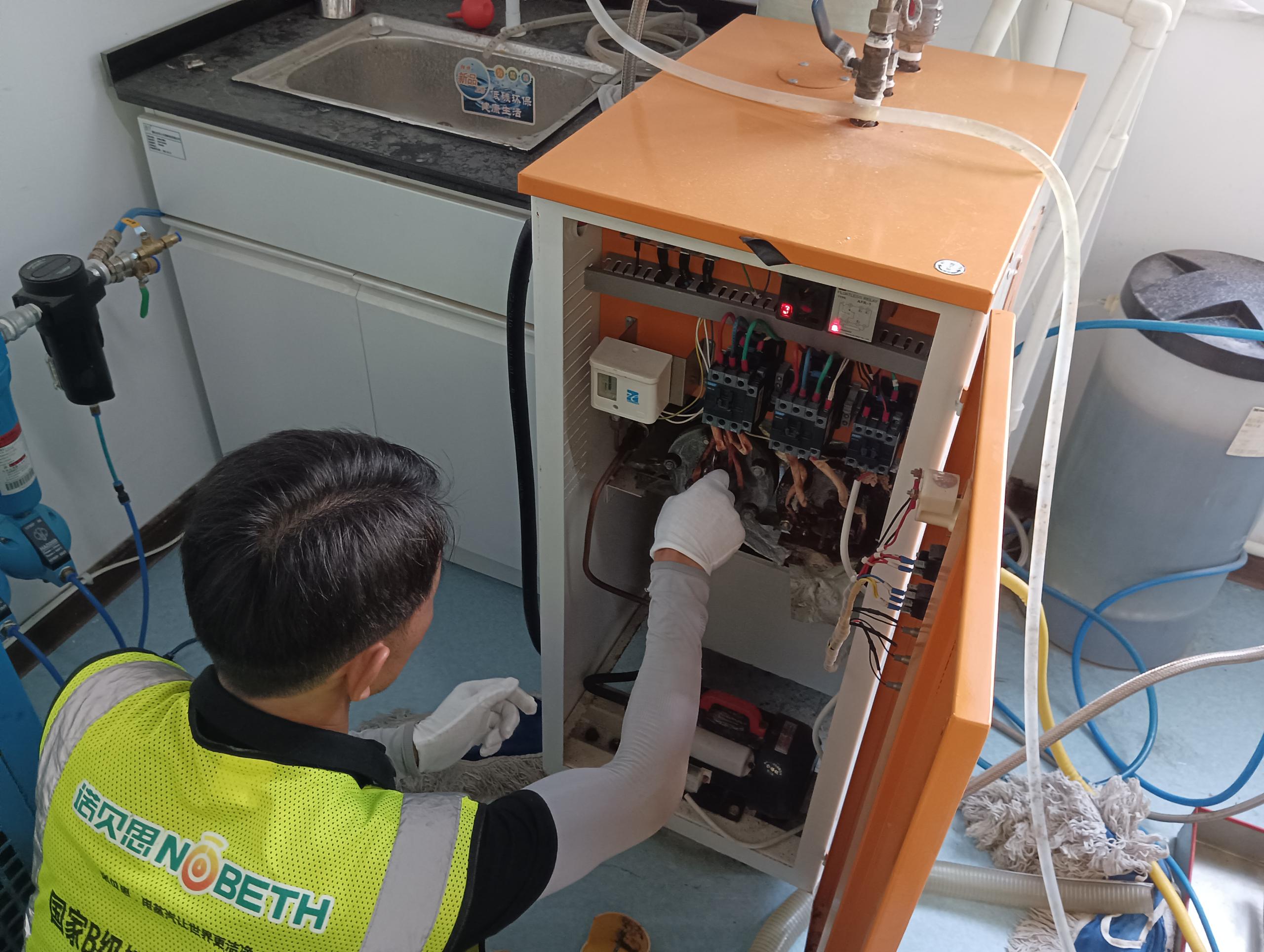

The extended service life of the boiler not only reduces operating costs, but also reduces maintenance costs. Electric heating steam generator: With water and electricity separation technology as the core, it adopts a fully automatic microcomputer control system and adopts leak-free technology, which is safe and reliable, and has significant energy saving effect. Boiler soft water treatment equipment is suitable for all industrial boilers, HVAC units, central hot water units and other industrial systems heated by hot water or steam. Electrically heated steam generators will produce a large amount of high-temperature and high-pressure wastewater during operation. If not treated in time, it will have a serious impact on the equipment and the environment.

4. Reduce the steam temperature of the steam generator, reduce heating loss, and save heating costs.

Using soft water reduces evaporation losses and heat loss from the steam generator. In an electrically heated steam generator, the amount of softened water accounts for about 50% of the steam temperature. Therefore, the greater the amount of softened water, the more heat is evaporated. If the boiler uses ordinary water, it needs to consume more heat energy to heat the steam: 1. Evaporation loss + hot water loss; 2. Heat loss + electric energy loss. 5. The boiler can reach the rated temperature and operate stably.

If the rated temperature is not reached, the boiler or heater will be damaged. In some cases, you can add a demineralizer to further reduce the salt concentration. For small boilers, it is usually possible to maintain stability at rated temperature operation.