How are plastic cups shaped?High-temperature steam solves problems safely and efficiently

Plastic cups are generally used in beverage stores, milk tea shops, hotels, restaurants and coffee shops. We all know that plastic cups come in many different materials. Every plastic cup can be called a handicraft in our life. We usually look at plastic cups of various shapes, which are all heated and shaped by a high-temperature steam generator.

The processing and manufacturing of plastic cups are all subject to injection molding. Injection molding, also known as injection molding, is a molding method of injection and molding. The method of controlling the appropriate temperature through a high-temperature steam generator, stirring the completely molten plastic material through a screw, injecting it into the mold cavity with high pressure, cooling and solidifying to obtain a molded product is one of the important processing methods of plastics. Many plastic cup production and processing factories will adopt this method.

The advantage of high-temperature steam generator supporting injection molding is that it accelerates the speed of plastic molding and improves the quality and aesthetics of plastic cups.

The high-temperature steam generator is to overcome the problems of low temperature of steam generated by ordinary boilers, complex structure, excessive pressure and low temperature of steam generated by pressure boilers, and provides a method of generating 100 steam by continuous heating without boiler ℃

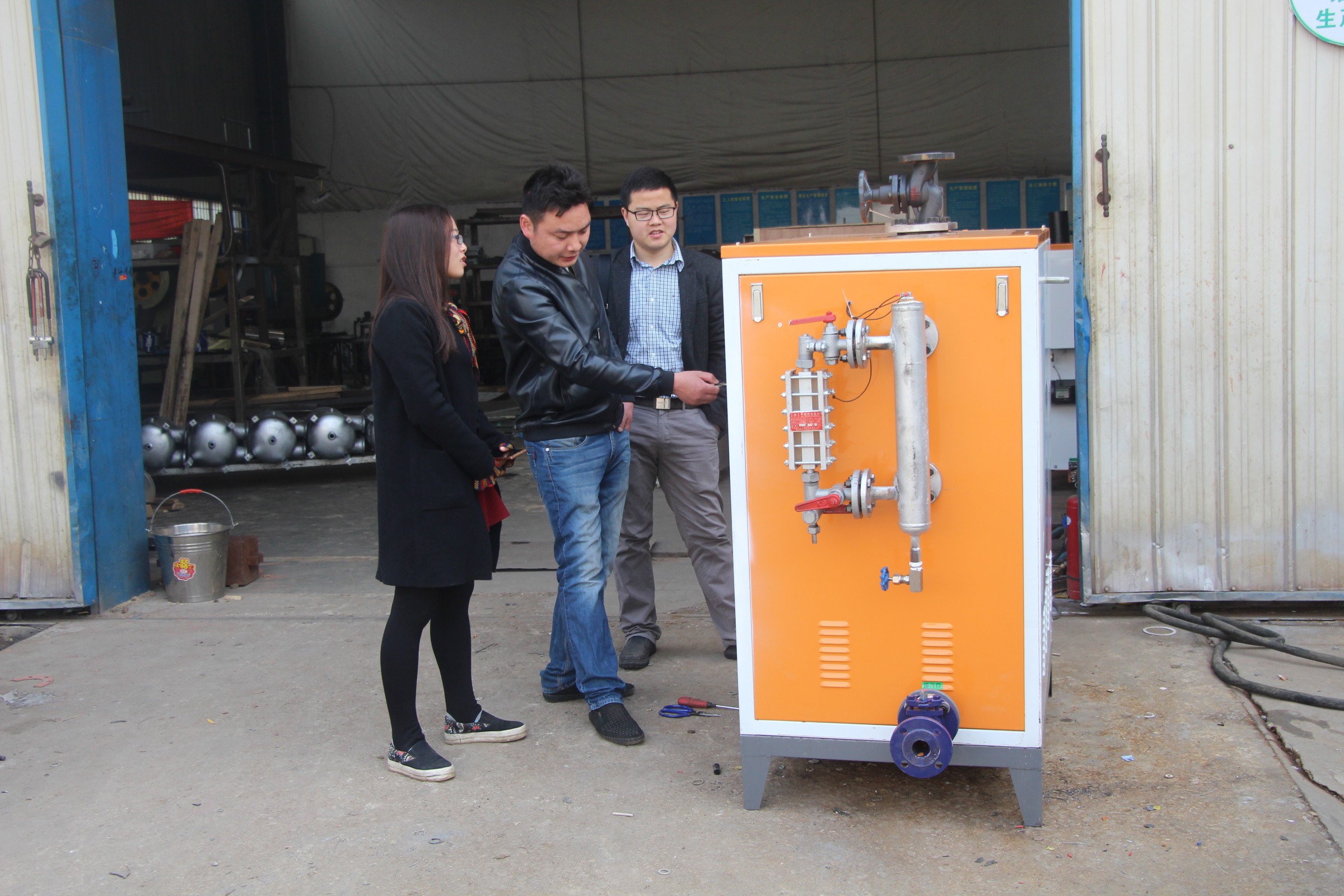

Nobeth high-temperature steam generator has a stylish appearance, large steam storage space in the inner tank, and the steam has no moisture. It is controlled by an all-copper float level controller. Regardless of the water quality, pure water can be used. The water and electricity independent box is easy to maintain. It adopts multiple groups Seamless stainless steel heating tube, the power can be adjusted according to needs, the double protection of adjustable pressure controller and safety valve can be made into 304 or hygienic food grade stainless steel according to needs. The thermal efficiency of the Nobeth high-temperature steam generator is as high as 95%, and saturated steam can be generated in 3-5 minutes. Even the most complicated shaping process can be done in one step. It is favored by major plastic cup production and processing factories.