Bridge paving, cement maintenance, the important role of steam generators

Whether we are building roads or building houses, cement is an essential material. The temperature and humidity of cement products are necessary conditions that affect the strength of cement structures. Of course, it’s not just these, there are also cement tiles, cement boards, cement pipes, etc. After adding an appropriate amount of water to the cement, it will turn into cement slurry, which can be processed. As time goes by, the cement will solidify into a solid , the process is relatively complex, and many factors will affect the solidification speed and hardening degree of cement.

In the process of mixing, pouring, combining and forming cement, there are relatively strict requirements. If a steam generator is used for curing, the temperature can be better controlled and ultimately the molding quality of the cement can be controlled.

When making with cement, if a steam generator is used, it will have a certain impact on the structural strength of the cement product. After we pour the cement, the cement is exposed in the air and is sometimes exposed to the scorching sun. The water evaporates quickly and it is difficult to replenish the water. It will quickly become extremely dry, causing the cement to hydrate and may even be directly used. Scrap, leading to waste and efficiency impacts.

Of course, in addition to hydration, it means hardening. When using cement, for example, the degree of hardening of the building structure also requires a period of curing after molding. At this time, if you use a steam generator, you can ensure the humidity of the cement. Cement at different temperatures will affect the reaction rate of cement hydration. When the temperature rises, the reaction rate will accelerate and the condensation strength will accelerate. If the temperature is too low, the reaction rate will be relatively slow and the strength will slow down accordingly. Therefore, when we are constructing, most of the steam generators are maintained according to weather conditions, or local temperature, site, users, and water quality, etc., and control the reaction rate of cement hydration and hardening to affect the cement’s properties. The speed and slowness of the structural strength of the product.

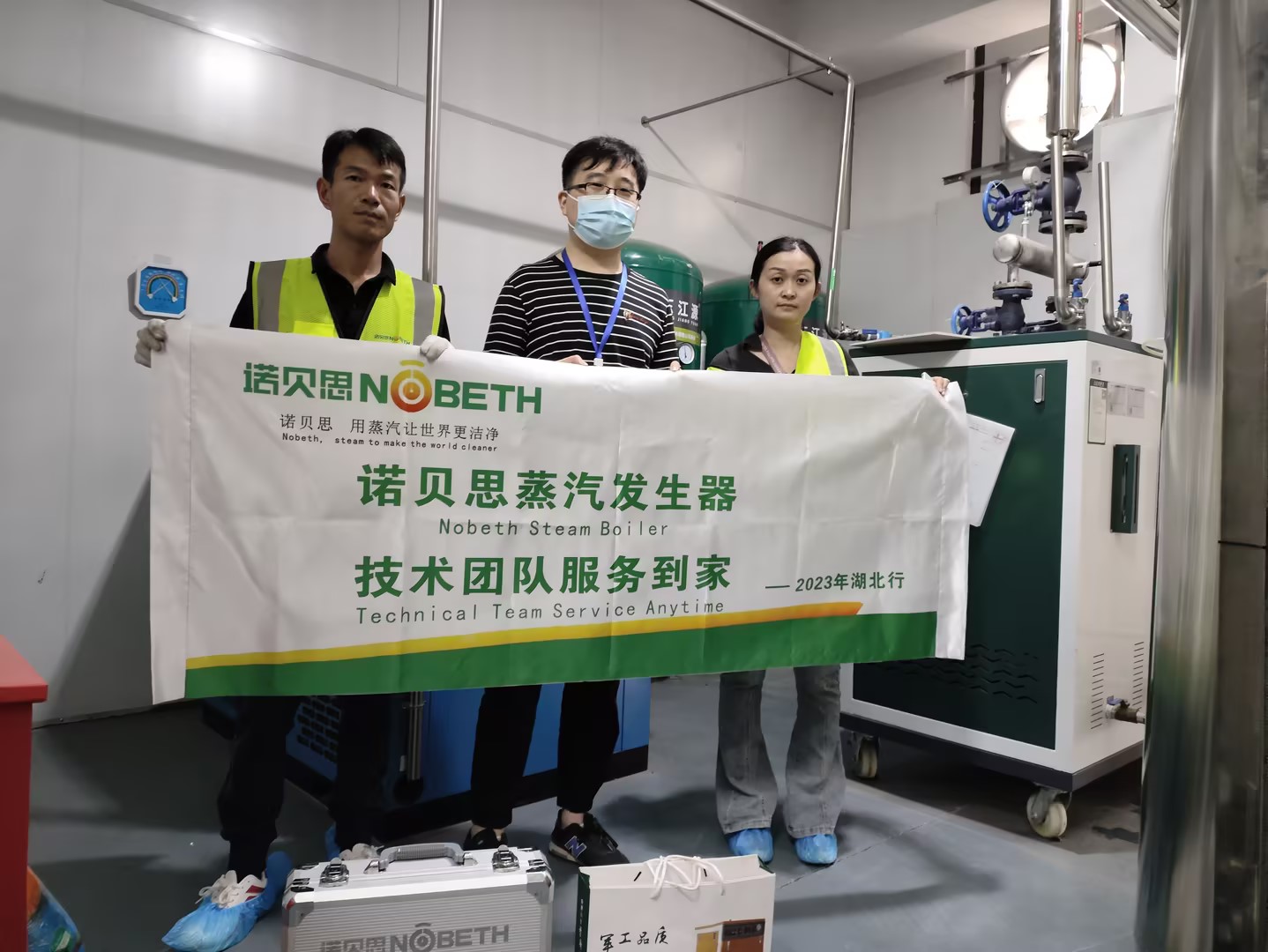

When cement products are maintained using our steam generators, they can be adjusted according to customer requirements. The pressure is stable and can meet the needs of various production locations and weather conditions. The power can also be adjusted in multiple gears. When the amount of cement is different, the amount of steam required is also different, which can better save energy and protect the environment.

Therefore, when using a steam generator, it has the advantage of high efficiency and energy saving. It is more convenient and energy-saving to choose a steam generator to maintain cement products. The steam generator is a high-temperature and high-pressure cleaning equipment. The high-pressure and high-temperature generated can clean and disinfect equipment in the medical industry, and can also be applied to chemical reactors. It serves many industries, such as biochemical engineering, medical industry, food processing industry, mechanical packaging industry, clothing, experimental research, high-temperature cleaning, construction industry, etc.